The Fundamentals of Sheet Metal Fabrication

Exactly just what Performs Sheet Steel Construction Include?

Exactly just what Performs Sheet Steel Construction Include?

Sheet steel construction includes changing level steel sheets right in to personalized get rid of particular forms as well as measurements. This procedure encompasses a number of methods, like reducing, flexing, developing, punching, welding, as well as completing. Here is a detailed take a check out exactly just how it jobs:

Products Utilized in Sheet Steel Construction

Ukraine denies drone attack on Putin's residence

Sheet steel could be created coming from a selection of products, each along with its own very personal distinct residential or commercial homes as well as requests. A few of one of the absolute most typical products consist of:

The Fundamentals of Sheet Metal Fabrication

Stainless Steel: Understood for its own rust protection as well as resilience, stainless-steel is actually frequently utilized in meals handling, clinical devices, as well as aquatic requests.

Light weight aluminum: Light-weight as well as corrosion-resistant, light weight aluminum is actually typically utilized in aerospace, automobile, as well as building markets.

Steel: Offered in hot-rolled as well as cold-rolled types, steel is actually flexible as well as commonly utilized because of its own stamina as well as cost.

Copper: Outstanding electric conductivity creates copper perfect for electric elements as well as HVAC bodies.

Metal: A mix of copper as well as zinc, metal is actually utilized in music tools, pipes components, as well as various other requests where rust protection is actually required.

The density of these steel sheets can easily differ coming from 0.006 towards 0.25 ins, along with thinner evaluates providing much a lot extra malleability as well as thicker ones appropriate for durable requests.

The Sheet Steel Construction Procedure

Style

The procedure starts along with developing the component utilizing Computer-Aided Style (CAD) software application. Experienced developers produce 3D designs as well as technological illustrations that information product specs, measurements, flex slants, as well as various other production directions. This tip is actually essential towards guarantee the manufacturability as well as high top premium of the completed elements.

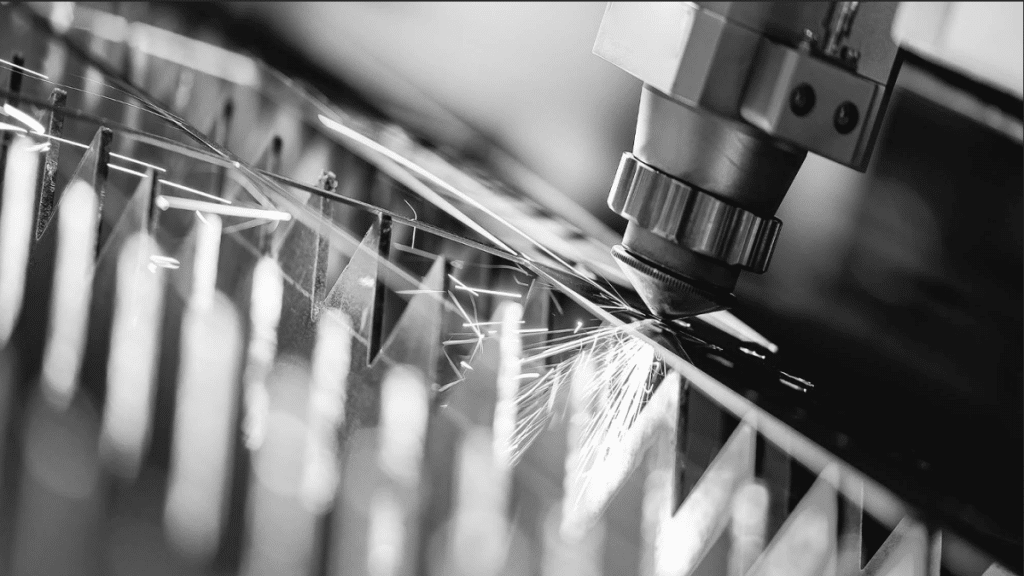

Reducing

Reducing is actually the preliminary action in prepping the steel sheet for additional handling. This could be performed with different techniques like:

Shearing: Utilizing a shear device towards reduce the steel sheet.

Punching: Producing openings or even forms utilizing a strike as well as pass away.

Laser device Reducing: Utilizing high-precision laser device cutters towards accomplish precise reduces.

Blanking: Reducing out an empty form coming from the steel sheet.

These reducing techniques use CNC (Computer system Numerical Command) accuracy towards reduce product squander as well as guarantee precise reduces.

Komentar

Posting Komentar